With low-volume production, you can keep a minimum inventory or economically provide individual parts.

Additive manufacturing is ideal for producing finished goods, if

If you use a conventional production method, additive manufacturing is ideal for pilot programs or as a bridge to production while you are waiting for parts to come off the line.

1. production volumes are small(usually less than 1,000 units per year)

2. life cycles are short or there are many product options.

Additive manufacturing doesn’t involve tooling. This slashes upfront time and cost and means you can make very complex parts simply and cost effectively.

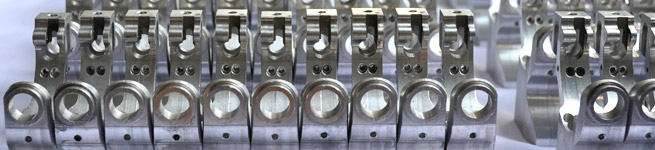

Options for low-volume production

In the earliest manufacturing, a skilled craftsman created goods one by one. The demand for cheaper and faster products led to factories and mass production. Now, high-quantity production facilities churn out millions of products each year.

But what if you only need to produce 1,000, 100, or even 10 per year? Low-volume manufacturing is fairly common in the medical device industry, for instance, as new concepts are tested in pilot markets or in clinical trials before larger volumes are necessary. Manufacturing processes, design options, and product aesthetics become limited as the costs of tooling and setup become more significant components of the project budget. Vendors are less inclined to respond, and client expectations require more active management. There are, however, opportunities among the challenges.

For high-quantity production, the initial investment spreads across the parts. For low-quantity production, though, capital investment can overwhelm the part cost. There is a balancing act among desired features, cost, and speed. Using commercial off-the-shelf parts in low-volume production limit aesthetics and creativity.

Designing complex products for low-volume production usually requires compromise. By understanding the limitations of each process, an engineer can tailor designs to make great parts with low-volume techniques. In addition, a designer can amplify the part count by making the left and right sides the same or by using the same part in multiple places. The principles of design for manufacture extend to all processes.

Educate clients about the challenges and compromises of low-volume manufacturing early, so that everyone knows what to expect. Understand the fabrication volume and select an appropriate manufacturing process early so the design can be optimized for the best form and function. This is generally better than trying to push the limits of a manufacturing technology to achieve something for which it is not appropriate.

Vendors can be one of the more frustrating challenges in low-volume manufacturing. In mass production, more product equals more money. Vendors tend to be less responsive to small-quantity orders unless they are specifically set up for that scale. The key is finding vendors that specialize in lower-volume production. They will be set up to run several small jobs at once with easily configurable manufacturing and assembly areas. However, it is important to confirm their capabilities and process controls.

When ordering off-the-shelf parts, try to use parts that come in standard sizes or have multiple sources. If a part is discontinued, another can be substituted without requiring a substantial product redesign. When this kind of backup is not possible, a low-volume manufacturer must rely on a single-source part. In that case, develop contingency plans in case the part becomes obsolete.

While low-volume manufacturing has its challenges, it also offers advantages. By using processes suited to small batches, prototype and production units can have similar components and materials. This enables early performance testing and preliminary verification and validation exercises, reducing the surprises that can show up in first article builds.

Being aware of the challenges involved with design for low-volume manufacture early in the design process can make it much easier. Knowing the limitations of the processes can shorten design time and help with managing clients’ expectations. You may need to make compromises but, with good design practices and some ingenuity, it is possible to bring a successful, aesthetically pleasing product to market in low volumes within a reasonable budget.

For more information, please contact: stefan@smartprototype.net